Cooling Towers

Functions

Cooling Towers have one function:

- Remove heat from the water discharged from the condenser so that the

water can be discharged to the river or recirculated and reused.

Some power plants, usually located on lakes or rivers, use cooling towers as a method

of cooling the circulating water (the third non-radioactive cycle) that has been heated in

the condenser. During colder months and fish non-spawning periods, the discharge from the

condenser may be directed to the river. Recirculation of the water back to the inlet to

the condenser occurs during certain fish sensitive times of the year (e.g. spring, summer,

fall) so that only a limited amount of water from the plant condenser may be discharged to

the lake or river. It is important to note that the heat transferred in a condenser may

heat the circulating water as much as 40 degrees Fahrenheit (F). In some cases, power

plants may have restrictions that prevent discharging water to the river at more than 90

degrees F. In other cases, they may have limits of no more than 5 degrees F difference

between intake and discharge (averaged over a 24 hour period). When Cooling Towers are

used, plant efficiency usually drops. One reason is that the Cooling Tower pumps (and

fans, if used) consume a lot of power.

Major Components

Cooling Tower(Supply) Basin

Water is supplied from the discharge of the Circulating Water System to

a Distribution Basin, from which the Cooling Tower Pumps take a suction.

Cooling Tower Pumps

These large pumps supply water at over 100,000 gallons per minute to one

or more Cooling Towers. Each pump is usually over 15 feet deep. The motor assembly may be

8 to 10 feet high. The total electrical demand of all the Cooling Tower pumps may be as

much as 5% of the electrical output of the station.

Cooling Towers

There are 2 types of towers - mechanical draft and natural draft

Mechanical Draft Towers

|

Mechanical draft Cooling Towers have long piping runs that spray the water

downward. Large fans pull air across the dropping water to remove the heat. As the water

drops downward onto the "fill" or slats in the cooling tower, the drops break up

into a finer spray. On colder days, tall plumes of condensation can be seen. On warmer

days, only small condensation plumes will be seen. |

|

Courtesy NSP |

Natural Draft Towers

|

This photo shows a single natural draft cooling tower as used at a

European plant. Natural draft towers are typically about 400 ft (120 m) high, depending on

the differential pressure between the cold outside air and the hot humid air on the inside

of the tower as the driving force. No fans are used. Whether the natural or mechanical

draft towers are used depends on climatic and operating requirement conditions. |

|

Courtesy KKN - Liebstadt NPP |

Simplified Diagrams

The diagrams below illustrate the arrangement of components within the

system and the major flow paths.

Forced - or Natural Draft Cooling Tower

|

The green flow paths show how the water is taken from a

river (yellow) to an intake supply basin (green) that the Circ Water Pumps take a suction

from. The water is then pumped to the Condenser where the water is heated. The water is then sent to an exit distribution basin where the water then can be

returned to the river and/or pumped by the Cooling Tower Pumps to the Cooling Towers then

the water returned to the intake supply basin where the water can be reused. |

|

|

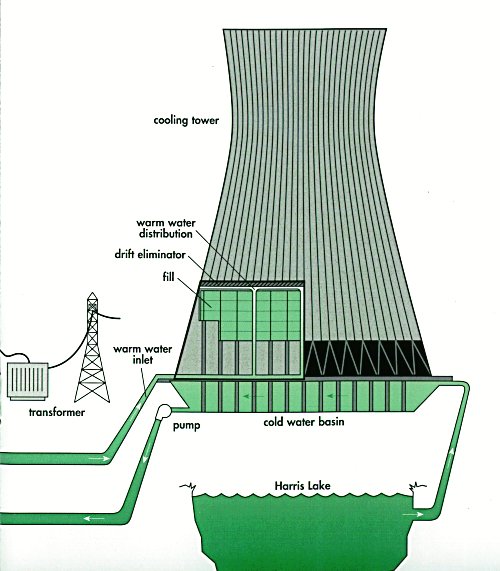

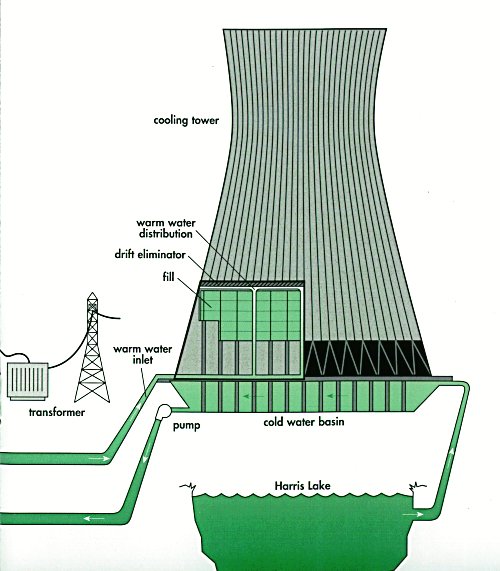

Natural Draft Cooling Tower

|

The green flow paths show how the warm water leaves the

plant proper, is pumped to the natural draft cooling tower and is distributed. The cooled

water, including makeup from the lake to account for evaporation losses to the atmosphere,

is returned to the condenser. |

| Courtesy CP&L |

|

Copyright © 1996-2004. Joseph

Gonyeau, P.E.. The Virtual Nuclear

Tourist. All rights reserved. Revised: March 15, 2001.