Callaway & Wolf Creek - The SNUPPS

Plants

In the 1970's, 4 utilities - Kansas Electric, Northern States Power, Rochester

Gas & Electric, and Union Electric - started on a path to design and build 6

standardized units. Due to depressed electrical demand following the oil embargo and the

uncertainty involved with licensing new reactors following the TMI event, NSP and RG&E

cancelled the Tyrone and Sterling facilities. Kansas Electric and Union Electric, with

Bechtel as the architect-engineer and Westinghouse as the nuclear equipment supplier

subsequently completed the design, built, and started up the Wolf Creek and Callaway

plants. Both are 4 loop Westinghouse PWRs.

Callaway is located in Fulton county about 100 miles northwest of Saint Louis,

Missouri. Ameren Corporation provides a page about Callaway

with history.

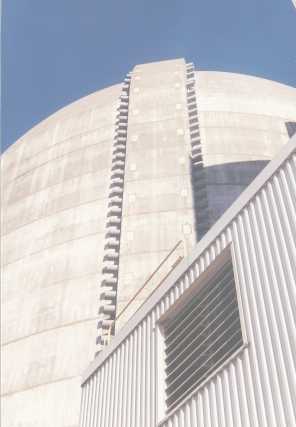

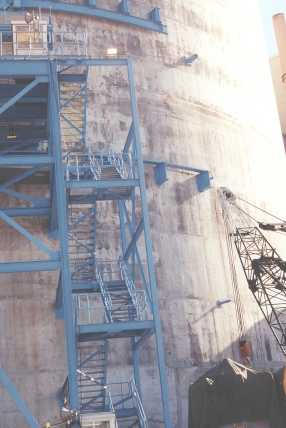

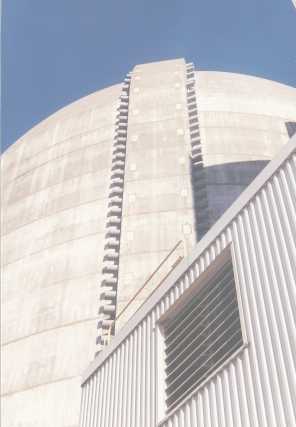

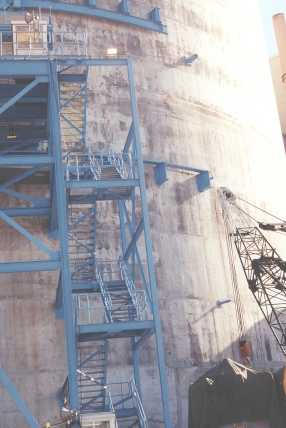

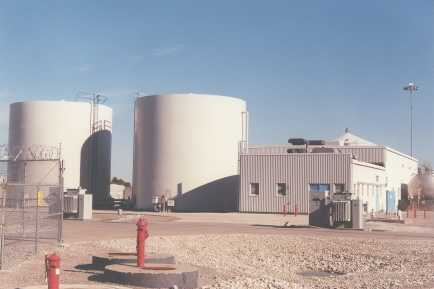

Below are some photos of the Callaway facility.

Wolf Creek Nuclear Operating Company

provides pages on the following topics:

The following are colored perspective and arrangement drawings of

The flow paths are illustrated by a colored graphic flow diagram

and a black and white line

drawing. The following describes the flow path and the linked drawings illustrate, in

detail, the composition and major parts of the components.

- Reactor - this

diagram shows how the reactor is constructed with its major components. Water at 530F

enters the reactor from the nozzles at about mid-height. The water flows downward on the

outside of the core barrel to the bottom of the reactor. Then the flow turns upward past

the fuel assemblies, removing

heat from the assemblies and increasing in temperature to 590-600F. After leaving the core

area, the water mixes in the upper plenum and leaves the reactor through nozzles. Flow

then goes to the

- Steam Generator

where the radioactive Reactor Cooling System water enters at the bottom, flows through

small inverted U-tubes. That water loses its heat as it passes through the tube being

cooled by the non-radioactive water outside the tube. Non-radioactive feedwater enters

through the nozzles at the mid-height of the steam generator at a temperature of about

425F. The water flows downward outside a wrapper sheet to the area just above the

tubesheet where the water turns and flows upward past the U-tubes. The water increases in

temperature and turns to steam. A moist steam at about 510-547F with pressure of 720-1005

pounds per square inch is produced. The moist steam travels upward to steam separators

(chevron separators and swirl vanes) which allow 99.75% purity steam to pass of the steam

generator and the remaining water is directed back to the lower part of the steam

generator. The reactor cooling system water enters the steam generator at ~590F and leaves

at ~ 530F. That water then flows to the

- Reactor Coolant Pump

which pumps the water back to the reactor.

- Pressurizer is used

to control the pressure in the reactor cooling system so that boiling does not occur in

the reactor. The pressurizer also is used to act as a surge tank for the system taking up

the level variations in the system. Heaters are installed at the bottom of the pressurizer

for heating the water to 652F and 2250 pounds per square inch. Automated pressure control

valves (called power operated relief valves) and safety valves, connected to the top of

the pressurizer, can open to control and maintain pressure.

- Secondary Systems

line drawings identifying major sub-components in the non-radioactive part of the system

where steam flows to the turbine, condenses in the condenser, then is pumped back to the

steam generator first by condensate pumps, then by feedwater pumps. The feedwater heaters

improve the efficiency of the cycle by recovering and reusing energy that would otherwise

be lost. By doing so efficiency of the cycle is raised to 33%.

Specifics on various plant systems including drawings are available in the NRC

plant information books for Callaway

and Wolf Creek.

Copyright © 1996-2004. Joseph

Gonyeau, P.E.. The Virtual Nuclear

Tourist. All rights reserved. Revised: March 15, 2001.